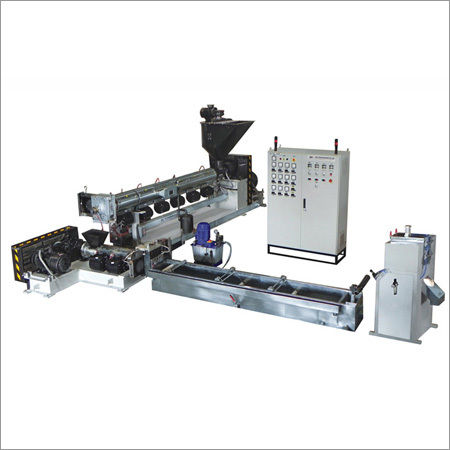

Product Description

Due to our proficiency in this domain, we are known to be one of the famous manufacturers, and suppliers of Extruder Granulation Plant. Our offered plant is used for mixing and granulating various ingredients used for different industrial products like pharmaceuticals,chemicals, foods and various others. Made in accordance with set international quality norms using latest techniques, the provided mixer is made by using best in class quality components by our adroit professionals. In addition to this, customers can get this Extruder Granulation Plant from us in various technical specifications at cost-effecting rates.

Specification:

- Palletizer for produce pallets.

- Cooling tank fabricated from S.S

- Heating control by temperature controller

- Barrel heating by power saving heaters

- Heavy helical gear box in built thrust housing

- Cooling system offered for perfect temperature control

- Control Panel having digital temp controller & accessory

- Drive from main A.C. motor to screw is through rubber belts & pulleys and a gear unit

- Granulation plant offered in standard, vented and high L/D ratio version, having screw & barrel made from alloy steel and fully nitriding, hard crome plating.

Efficient Semi-Automatic OperationThis extruder granulation machine is designed to streamline production with semi-automatic controls. Operators can easily manage settings, while frequency speed control ensures consistent granule output. Its balance of automation and manual oversight delivers both precision and adaptability, ideal for evolving manufacturing needs.

Durable Stainless Steel BuildConstructed entirely from stainless steel, this machine promises durability, corrosion resistance, and hygienic processing. Its robust frame stands up to rigorous industrial environments, safeguarding your investment and ensuring uninterrupted operations while maintaining product quality standards.

User-Friendly and Reliable Control SystemEquipped with a reliable frequency speed control system, this machinery offers adjustable operating speeds for varying production demands. Its non-computerized design reduces complexity, enables easy troubleshooting, and minimizes downtime, making it ideal for manufacturers prioritizing simplicity and consistency.

FAQ's of Extruder Granulation Machine:

Q: How does the extruder granulation machine work?

A: The machine operates by using an electric drive to articulate feed material through an extrusion process. The frequency speed control allows the operator to set and adjust the extrusion rate, resulting in the formation of uniform granules. Semi-automatic controls make it easy to monitor and adjust throughout the process.

Q: What materials can be processed with this machine?

A: Designed with versatility in mind, the extruder granulation machine can handle various substances, primarily targeting plastics and similar compounds. Its stainless steel construction ensures compatibility with a range of materials while maintaining hygienic standards and preventing contamination.

Q: When is this machine most beneficial in production?

A: This machine is especially advantageous for medium- to large-scale manufacturing setups requiring consistent granule production. Its semi-automatic operation provides a balance of manual control and automation, making it suitable for operations needing adaptability and reliable throughput.

Q: Where is this machine commonly used?

A: Predominantly utilized in industrial and manufacturing settings across India, this machine finds a place in sectors like plastics processing, chemical granule production, and related industries where granulation is a key step in the production process.

Q: What are the primary benefits of frequency speed control for this equipment?

A: Frequency speed control allows operators to fine-tune the granulation process, optimizing output for different material types and sizes. This feature leads to reduced material waste, improved granule uniformity, and enhanced operational efficiency within the facility.

Q: How should the machine be maintained for optimal performance?

A: Routine maintenance involves regular cleaning of the stainless steel components, periodic inspection of moving parts, and ensuring the electric drive operates smoothly. Adhering to manufacturer guidelines helps extend the machine's lifespan and maintain consistent performance.